Nupress embraces

5s and LEAN

manufacturing principles to deliver successful outcomes.

Cyber Facility

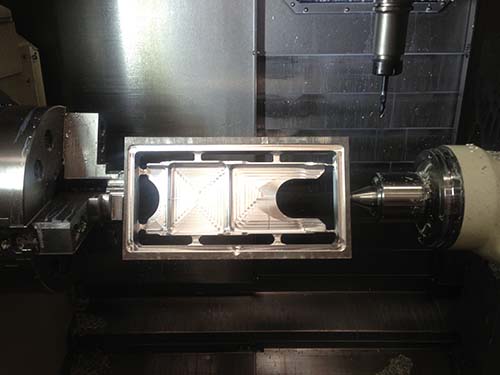

To compete in an increasing competitive international marketplace Nupress’ focus is on working smarter not harder. Our innovative manufacturing approach positions us for the manufacture of unique and complex parts while also excelling in high quantity batch manufacturing.

Technologies

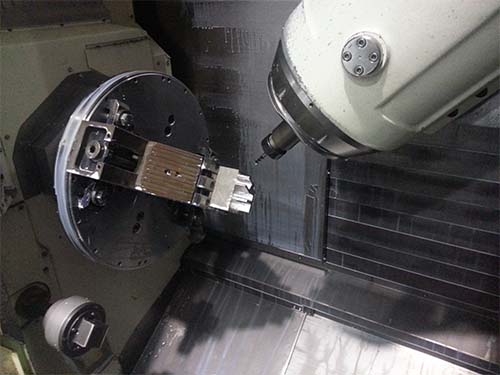

Nupress commitment to first class manufacturing technologies led to the decision to have our facility exclusively Mazak CNC machines. Mazak are the largest tool providers in the world and are at the forefront of CNC technology.

Nupress commitment to a collaborative approach led to the implementation of a Sandvik Tooling Crib. Sandvik are the market leader in tooling consumables and with their technology in our tooling room we are able to ensure on time ordering of all our tooling needs.

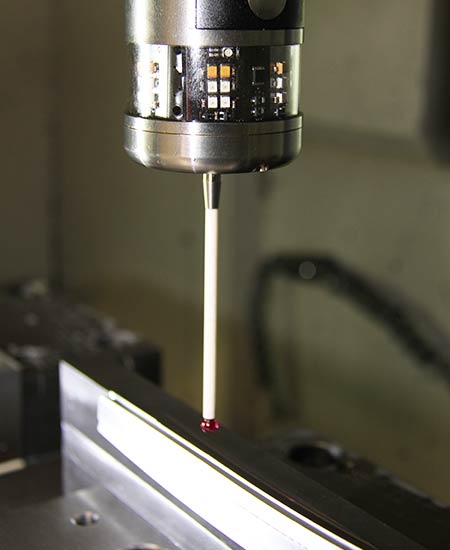

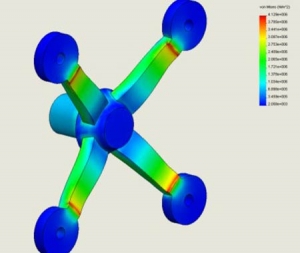

Reverse engineering

Is the process of extracting knowledge or design information from a part and or assemblies. The process often involves disassembling something and analysing its components and workings in detail.

At Nupress we bring the latest technology as well as generations of mechanical design to the table.

Capabilities

|

Precision MachiningNupress precision CNC machining facility is exclusively furnished with current generation Mazak machine tools with capabilities listed below.

|

Engineering

The most difficult task in any engineered product is to bring together the design intent with an engineered solution. We realises the time and cost impact of these two parameters and for that reason has developed a full circle solution.

Engineering , shop and manufacturing drawings are about turning our clients design or vision into reality. The design and engineering staff at Nupress are there to work with you and your project, to provide first class engineering solutions. We understand the time constraints on many projects and use the latest in hardware and software to achieve concurrent results.

As drawings become available our manufacturing staff can be producing samples for customer approval. As you know research and development forms a big part of engineering. We are committed to open discussion and listening to our client’s design intent. This collaborative approach provides confidence in the complete system, starting with the vision and finishing with the reality.

|

Castings and ForgingsFor a Single Point Solution for forging and casting requirements and post cast/forged processing. We are conversant with hot and cold forging methods and have a proven track record in post forge machining techniques.

Using: Stainless steel, Titanium, Ferrous, Non ferrous and Aluminium. |

|

Welding and FabricationNupress has vast experience in welding and fabrication parts all complying with AS1554. We carry out in house macro and destructive testing. We also use independent third party testing and verification. Types of welding techniques used:

|

|

Assemblies and FinishingNupress has a long history of supplying fully assembled and finished products and components. We follow our documented QA inspection and assembly procedures. |

Quality Assurance and TestingNupress is a AS9100-REVC and ISO 9001-2008 certified company. Nupress works with our clients to meet their individual quality documentation needs. Our quality assurance system demonstrates our ability to consistently provide products and services that meet customer and applicable regulatory requirements through the entire process from quotation to delivery, including: |

|

|

| Our quality system meets the requirements for the design development, manufacture and machining of components including casting fabrications, tools, jigs and fixtures for the mining, building, construction, aerospace, defence, food processing and glass wall facade industries. |